Continuous Improvement

A Balanced Ecosystem Approach Drives Better Industrial Technology Results

Buying solutions in manufacturing can be a complex process. There is no shortage of technology solutions available, with the range of hardware and software options enough to create great potential for second guessing and doubt.

- Adam Napolitano

- Triple Circle Partners

Detecting Elusive Loose Electrical Connections

Intermittent faults caused by loose electrical connections are difficult to detect with standard inspection methods, and if left unchecked they can be expensive and dangerous. Is it possible to flag these problems early without breaking the bank?

- Brad Nanna

- IRISS Inc.

RCA: Going From Good to Great

In this paper, I would like to remove the RCA provider brand labels, and delve into ‘What makes any RCA effort, good versus great?” When we remove the labels and look at any investigative occupation, all the steps are basically the same.

- Robert Latino

- Prelical Solutions

Case Study of NASA Webb Telescope via Ferrography and More

Ferrography has been around since the 1970’s invented by Vernon Westcott due to a need to observe wear particles/Ferrography in the 5–350-micron range. Most believe this is the particle size range to detect potential failure prior to any mechanical problems. However, the ferrography analysis was thought to be time consuming, expensive, and non-repeatable.

- Ray Dalley

- Trico Corporation

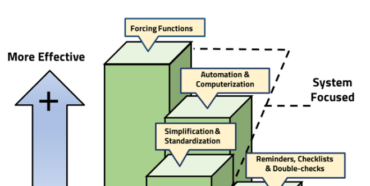

9 Principles of an Effective PM Program based on Reliability Centered Maintenance (RCM)

In this article, I provide a brief history of the development of Reliability Centered Maintenance (RCM). And from there we explore 9 principles derived from RCM that will help you build an effective Preventive Maintenance Program.

- Erik Hupje

- R2 Reliability

RCM Graphs and P-F Interval Graphs – Are they useful?

RCM graphs and P-F interval graphs, of one form or another are often cited as the basis for an effective maintenance and reliability program. But are they useful?

In this podcast we’ll explore the use of these representations and how they can be used tactically and strategically to better manage an industrial operation.

- Ron Moore

- RELIABILITY CONNECT

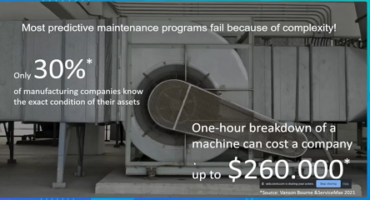

Why Do Most Predictive Maintenance Programs Fail?

Christian Benk, director of product management at B&K Vibro, draws from an industry study and his own experience to describe why most companies experience failure in their predictive maintenance programs…

- Christian Benk

- BK Vibro

Myths and Pitfalls of Planning & Scheduling – CONNECT Conversations

We’ll be reviewing the various pitfalls and myths associated with effectively installing a CMMS. For example, if the total number of defects coming into the process on a daily basis overwhelm your ability to effectively plan and schedule, the system will fail. We’ll review the importance of defect elimination, especially upstream of maintenance in operations and design, the importance of have a proper PM program, a proper condition monitoring program, the importance of integrating the production plan and the maintenance plan into a single plan, among other issues...

- Ron Moore

- RELIABILITY CONNECT

Repair or Replace? – CONNECT Conversations

Answering this question requires considerable information and analysis, and judgment. For example: What’s the current state of the asset? We’ll explore these and other questions, and provide guidance in helping you answer this fairly frequent, fundamental, and ofte3n complex question...

- Ron Moore

- RELIABILITY CONNECT

- 1

- 2

- 3

- …

- 10