Work & Spares

Join Us at Reliable Plant Conference 2025!

The Reliable Plant Conference & Exhibition, co-located with the Machinery Lubrication Conference & Exhibition, is a 4-day event dedicated to the latest trends and tactics in maintenance and reliability. With expert-led learning sessions, access to cutting-edge tools and technologies offered by over 100 exhibitors, and powerful networking experiences, this is a can’t-miss event for anyone looking to transform their maintenance strategy.

- Noria Corporation

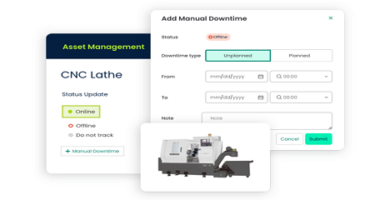

13 Reasons Why More Businesses are Implementing CMMS Software

What is it about Computerized Maintenance Management Software systems (CMMS) that makes it so attractive to a wide range of organizations across a variety of sectors? After all, before they were first introduced in the late 1960’s, companies seemed to manage quite well using standard pen and paper.

- Reena Sommer

- Click Maint

5 Effective Strategies to Improve User Adoption of CMMS Software

In today's fast-paced and technology-driven workplaces, Computerized Maintenance Management Software (CMMS) has become an indispensable tool for streamlining maintenance operations, enhancing productivity, and ensuring the longevity of assets.

- Reena Sommer

- Click Maint

DataConnect- the Answer for Data Integration

Today, we sit down with Randy Clark from Polaris Laboratories to discuss DataConnect. This is a way to integrate fluid analysis data with your CMMS, ERP platforms.

- Randy Clark

- Polaris Laboratories

What Are the Benefits of a CMMS?

Josh Burkhardt, an implementation specialist with eWorkOrders, goes through some of the most significant benefits of a CMMS. First, a CMMS helps you automate work requests…

- Josh Burkhardt

- eWorkOrders

Importance of Maintenance Management- Why You Need It

For most businesses, their assets and equipment are a large expense and a critical component of their core business operations. For instance, in manufacturing companies, shredders, mixers, generators, lifts, centrifuges, and conveyor belts all play crucial roles in turning raw materials into finished goods.

- Jeff Roscher

- eWorkOrders

Real World Examples of Inventory Management

I reached out to several business owners and other consultants to get their real world perspectives on inventory management techniques in their own industries.

- Jeff Roscher

- eWorkOrders

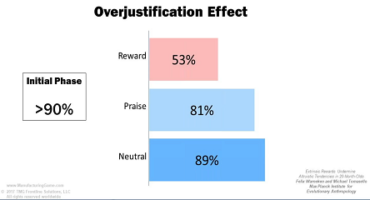

Certain Types of Motivation Actually Damage Work Performance

Michelle Henley has spoken about direct motivating factors (the P’s) and indirect motivating factors (the E’s). One of these enhances performance at work, and one actually decreases it. Scientific research backs this up, showing that…

- Michelle Henley

- TMG Frontline Solutions

Using Modern Software to Help with Manufacturing Standard Operating Procedures & Compliance

With Computerized Maintenance Management Software, or CMMS, monitoring compliance is simple. Manufacturers can automate SOP completion and preventive maintenance operations to enhance the quality of products..

- Nick Haase

- MaintainX

- 1

- 2

- 3

- 4