Precision and Proactive Skills

Why Do Most Predictive Maintenance Programs Fail?

Christian Benk, director of product management at B&K Vibro, draws from an industry study and his own experience to describe why most companies experience failure in their predictive maintenance programs…

- Christian Benk

- BK Vibro

Crackdown on Piping Issues: A Geometric Survey of Pump Support Structure

The piping of this very large pump was about 10 feet in diameter, and structural cracks were forming. We measured the flatness of each individual bearing foot, and then measured that flatness against a best-fit plane of all four feet to check for soft foot. We also measured…

- Tony Planamento

- Advanced Mechanical Enterprises/AME

How a 3D Geometric Survey Diagnosed Faults in a Grounded Tugboat

We received a call regarding a tugboat that had run aground. Our survey included measurements of the hull mating flanges, Z-Drive cones, gearbox mounting flanges, bell housings, stems, and starboard lower gearbox housing for parallelism…

- Tony Planamento

- Advanced Mechanical Enterprises/AME

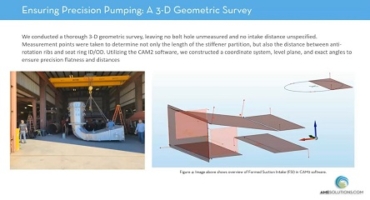

Ensuring Precision Pumping: A 3D Geometric Survey

We conducted a thorough 3D geometric survey of a submersible pump, leaving no bolt hole unmeasured and no intake distance unspecified. Utilizing the CAM2 software, we constructed a coordinate system, level plane, and exact angles to ensure precision flatness and distances…

- Tony Planamento

- Advanced Mechanical Enterprises/AME

Rosemary’s Car: How NOT to Treat Your Machines

Sometimes routine maintenance gets overlooked, as in the case with my friend’s car…

- Roy Giorgio

- AssetWatch

Episode 24: Butler Fuqua

Welcome to Veterans Connected! In this episode, Eric interviews Veterans Connected first Marine Corps Veteran, Butler Fuqua. Growing up in a military family, Butler describes his journey coming from small-town Alabama to coincidentally winding up in the Marine Corps enrollment office to eventually guarding President Obama on Marine One. Listen to Butler's adventures in the service and his eye opening life changes that have led him to his current endeavor in Hawaii...

- Eric Bevevino

- Veterans Connected

Episode 23: Carl Sullivan

Welcome to VETERANS CONNECTED Season Two! Maintenance and reliability expert and military Veteran Eric Bevevino interviews E5 Sergeant, Carl Sullivan. Born and raised in Kentucky, Carl takes us through his unusual enlistment in the Kentucky Army National Guard that sparked the beginning of his military career. Eric and Carl discuss Carl's personal inspiration for joining the National Guard, his connection to the Honor Flight Network, and his efforts to establish the innate value in veterans at Lexmark...

- Eric Bevevino

- Veterans Connected

Sensor Fusion: The Path to Proactive Plant Maintenance and Operational Excellence

A powerful approach for improving plant maintenance programs is the integration of multiple sensing technologies to improve coverage of machines and different failure modes. This can be further complemented by effective analysis of the data from all the different sources. When using multiple sensors like this, it is called Sensor Fusion...

- Alan McCall

- Sensoteq

The Benefits of Quantifiable Measures in Reliability Strategy Execution

Being able to take the next step in executing a reliability strategy often entails quantifying the value of taking on the effort. Often, there are subjective measures assigned, such as internal or external audit criteria, and some score that comes because of these audits. Where the rubber really hits the road is when we can connect the dots between what we are trying to accomplish and some clear and measurable source of value...

- Mike Gehloff

- Allied Reliability

- 1

- 2

- 3

- …

- 5