Precision and Proactive Skills

Contractor Management – CONNECT Conversations

Contractors are an essential part of any plant’s operating strategy. In this session we’ll review a “best practice” model for the effective use of contractors, including a set of contractor selection criteria.

- Ron Moore

- RELIABILITY CONNECT

Calculating the Costs of Ignoring Oil Analysis

Oil analysis can tell us a lot about the condition of a machine, and we ignore its potential at our peril…

- Roy Giorgio

- AssetWatch

Episode 22: Clark Smith

Welcome to VETERANS CONNECTED! Maintenance and reliability expert and military Veteran Eric Bevevino interviews Veteran's Connected first Vietnam Veteran, Clark Smith. In this episode, Clark and Eric chat about their 20-year friendship and Clark's journey from the Army to maintenance and reliability...

- Eric Bevevino

- Veterans Connected

Episode 21: Tim Harmon, Round 2

Welcome to VETERANS CONNECTED, Season Two! To kick off this new season, maintenance and reliability expert and military Veteran Eric Bevevino catches up with Army veteran Tim Harmon! Tim is a Project Manager for Allied Reliability. Tune in to hear Tim discuss his career development, where the potential lies in future engineers, and the reality of transitioning from combat to career...

- Eric Bevevino

- Veterans Connected

The Fundamentals of Belts and Sheaves

In some industries, like oiling, drive belt replacement is considered a task for the new guys on the floor. It’s an easy job right? Absolutely. But there are many ways to do it incorrectly if not taught properly the first time.

- Stan Riddle

- ACOEM

Plan for Success: Create a Schedule

Paul Dufresene explains how to prioritize work and meet deadlines when everything is a top priority. It is crucial to note the difference between what is urgent and what is important.

- Paul Dufresne

- Reliability Playbook

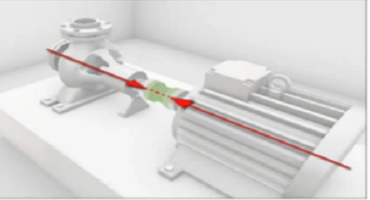

Precision Alignment Saves Energy

Significant power savings can be made through accurate alignment. Precise machine alignment eliminates reaction forces and reduces energy consumption by up to 10 percent.

- Sven Fleischer

- Easy-Laser

Playing it Safe — How to Avoid Arc Flash Explosions

Working around electrical equipment, it’s imperative to understand the potential hazard of arc flashes, what causes them, and how to prevent serious damage to people and assets. When electrical current passes through the air from one point to another, the resulting arc flash can reach temperatures up to 35,000° F. An arc flash is the light, concussive energy, and heat produced as part of an arc fault, a type of electrical discharge that results from a connection from phase to phase, or phase to ground.

- Mike Levitt

- Allied Reliability

Maintenance & Reliability in Practice Virtual Case Studies Event

Erin Erickson, the Executive Director of SMRP, answers questions about upcoming case studies event and other exciting news from SMRP.

- Erin Erickson

- Kellen

- 1

- 2

- 3

- 4

- 5