Case Studies and Stories

RYAM’s Transformative Journey

RYAM, an industry leader, proactively integrated KCF Technologies’ Comprehensive Machine Health Platform solutions into their operations – resulting in remarkable improvements.

- Jeremy Frank

- KCF Technologies

RCA: Going From Good to Great

In this paper, I would like to remove the RCA provider brand labels, and delve into ‘What makes any RCA effort, good versus great?” When we remove the labels and look at any investigative occupation, all the steps are basically the same.

- Robert Latino

- Prelical Solutions

Case Study of NASA Webb Telescope via Ferrography and More

Ferrography has been around since the 1970’s invented by Vernon Westcott due to a need to observe wear particles/Ferrography in the 5–350-micron range. Most believe this is the particle size range to detect potential failure prior to any mechanical problems. However, the ferrography analysis was thought to be time consuming, expensive, and non-repeatable.

- Ray Dalley

- Trico Corporation

9 Principles of an Effective PM Program based on Reliability Centered Maintenance (RCM)

In this article, I provide a brief history of the development of Reliability Centered Maintenance (RCM). And from there we explore 9 principles derived from RCM that will help you build an effective Preventive Maintenance Program.

- Erik Hupje

- R2 Reliability

Maintenance Efficiency in a Water and Air Treatment Plant

A plant in Poland was still performing costly interval-based maintenance on its water and air treatment utilities. They needed a more efficient solution at a reasonable price…

- Christian Benk

- BK Vibro

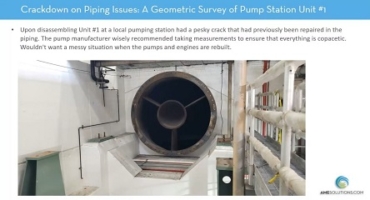

Crackdown on Piping Issues: A Geometric Survey of Pump Support Structure

The piping of this very large pump was about 10 feet in diameter, and structural cracks were forming. We measured the flatness of each individual bearing foot, and then measured that flatness against a best-fit plane of all four feet to check for soft foot. We also measured…

- Tony Planamento

- Advanced Mechanical Enterprises/AME

How a 3D Geometric Survey Diagnosed Faults in a Grounded Tugboat

We received a call regarding a tugboat that had run aground. Our survey included measurements of the hull mating flanges, Z-Drive cones, gearbox mounting flanges, bell housings, stems, and starboard lower gearbox housing for parallelism…

- Tony Planamento

- Advanced Mechanical Enterprises/AME

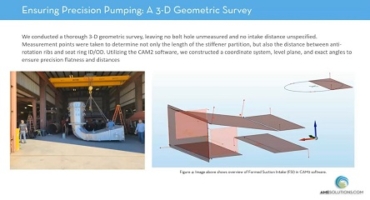

Ensuring Precision Pumping: A 3D Geometric Survey

We conducted a thorough 3D geometric survey of a submersible pump, leaving no bolt hole unmeasured and no intake distance unspecified. Utilizing the CAM2 software, we constructed a coordinate system, level plane, and exact angles to ensure precision flatness and distances…

- Tony Planamento

- Advanced Mechanical Enterprises/AME

Achieving a Proactive Maintenance Culture and Increasing Plant Reliability

In 2017, Worthington Industries embarked on a maintenance challenge. Their goal was to improve overall plant reliability and transform their maintenance and reliability division from a reactive culture to a proactive one. It was a visionary look toward the future for the global metals manufacturing company.

- Jaidev Krishnan

- AssetWatch

- 1

- 2

- 3

- 4