Continuous Improvement

Expectations, Execution and Engagement – Essential – CONNECT Conversations

It’s been our experience that the lowest standard you set is the highest standard you can expect. As such, your expectations (standards) should be fairly high, but achievable. It does little good to set expectations too low – too easy, or too high – assuring failure....

- Ron Moore

- RELIABILITY CONNECT

Maintenance Costs as a % of ARV – Is It Useful? – CONNECT Conversations

Maintenance Cost as a Percent of Asset Replacement Value is often used as a measure to determine the effectiveness of the maintenance function. But, is it? In this podcast we’ll discuss the various means of calculating its value, and by implication, some of its downsides, along with a range of its value for various operations and potential reasons for that variation.

- Ron Moore

- RELIABILITY CONNECT

Why Do We Measure OEE? – CONNECT Conversations

Manufacturing and other industrial operations are typically familiar with measuring OEE, but there is often confusion about how to measure, where to measure, the rate to use and other issues related to its measurement...

- Ron Moore

- RELIABILITY CONNECT

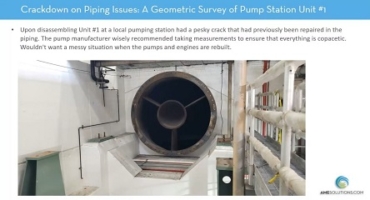

Crackdown on Piping Issues: A Geometric Survey of Pump Support Structure

The piping of this very large pump was about 10 feet in diameter, and structural cracks were forming. We measured the flatness of each individual bearing foot, and then measured that flatness against a best-fit plane of all four feet to check for soft foot. We also measured…

- Tony Planamento

- Advanced Mechanical Enterprises/AME

How a 3D Geometric Survey Diagnosed Faults in a Grounded Tugboat

We received a call regarding a tugboat that had run aground. Our survey included measurements of the hull mating flanges, Z-Drive cones, gearbox mounting flanges, bell housings, stems, and starboard lower gearbox housing for parallelism…

- Tony Planamento

- Advanced Mechanical Enterprises/AME

The P-F Curve We Were Taught Kills Productivity and OEE

Roy Giorgio demonstrates why the older model of the P-F Curve can be misleading, using an example of a conveyor gearbox in which problematic data was disregarded…

- Roy Giorgio

- AssetWatch

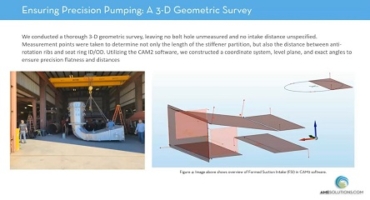

Ensuring Precision Pumping: A 3D Geometric Survey

We conducted a thorough 3D geometric survey of a submersible pump, leaving no bolt hole unmeasured and no intake distance unspecified. Utilizing the CAM2 software, we constructed a coordinate system, level plane, and exact angles to ensure precision flatness and distances…

- Tony Planamento

- Advanced Mechanical Enterprises/AME

Definitions: Reactive, Preventive, Predictive, and Proactive Maintenance – CONNECT Conversations

There are likely as many definitions for various types of maintenance as there are companies. The purpose of this podcast is to offer definitions for each of the types indicated in the title, and to provide the reasoning behind each...

- Ron Moore

- RELIABILITY CONNECT

Rosemary’s Car: How NOT to Treat Your Machines

Sometimes routine maintenance gets overlooked, as in the case with my friend’s car…

- Roy Giorgio

- AssetWatch

- 1

- 2

- 3

- 4

- …

- 10