Condition Monitoring

No, You Cannot Borrow My Truck

In 1951, the US Army began publishing PS Magazine. The idea was to publish a magazine about Preventive Maintenance that soldiers would actually want to read. They found an artist named Will Eisner and his company began creating artwork for the magazine. Eisner believed that comics had teaching potential and convinced many talented artists to help him. Each month contained a single-frame comic and an accompanying limerick called "Joe's Dope Sheet". Every month followed the story of Joe, a soldier who ignores preventive maintenance and learns of its importance in the end.

- Bill Barto

- RELIABILITY CONNECT

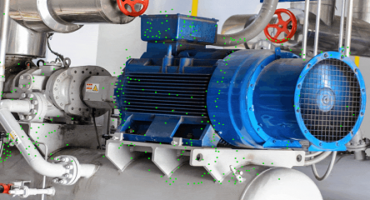

Motion Magnification Real-Life ODS

Real life ODS is a new way to visualize the vibration of a machine in the same way you used to do it using conventional ODS. Thanks to the technology developed by Erbessd Instruments you can collect data with your accelerometers and after that, just take a picture and you’re ready to complete a motion magnification analysis.

- Michael Howard, DSc

- ERBESSD-INSTRUMENTS

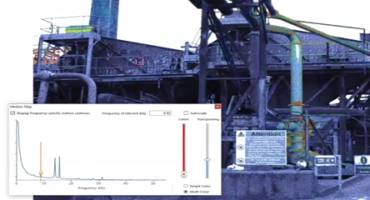

What is Motion Amplification®?

Motion Amplification® is a video-based vibration tool that allows users to visualize motion and measure displacement across the entire image. Watch the video to see how it works and how it fits with other tools in the reliability toolbox.

- Jeff Hay

- RDI Technologies

Avoiding Machine Failure with Oil Condition Monitoring

Lubricants, fuels and other key fluids analyses provide critical early warning information indicative of machine failure. By analyzing and trending data, one can schedule maintenance before a critical failure occurs. The results are higher equipment availability and productivity, lower maintenance costs, lower total cost of ownership (TCO), fewer outages, optimal equipment performance and a greener operation.

- Mentor APM

- MentorAPM

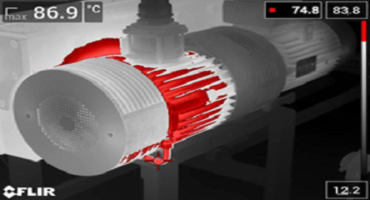

Reliability, Safety and Thermal Imaging

Have you considered how your role as a Reliability Engineer, and the decisions you make, affects the drive to a safer working environment? As Reliability Engineers we are in a unique position that allows us to influence the culture of a plant. We do so by education, demonstration and documentation of efforts, to improve the operation of the facility.

- PJ Cloete

- AVT Reliability

Electrical Reliability on the Grid Part V: Flywheel Storage

In the Federal government and commercial designs, there are a variety of designs including cylinders and solid mass systems. The mechanical components have lower failure rates with the effectiveness and reliability of magnetic and related guide bearings. The upper speed limit and resulting Watt-hour capability is based on the mechanical limits of the flywheel and shaft.

- Howard Penrose

- MotorDoc LLC

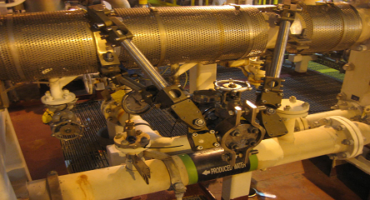

Why Is It Important To Assess Pipework Vibration?

In today’s Interview Simon Hurst from AVT Reliability discusses the importance of assessing pipework vibration, controls to ensure safety, small bore connections (SBC’s). Simon has spent over 25 years in the Vibration and Asset Industry.

- Simon Hirst

- AVT Reliability

Meet MOBIUS CONNECT Ambassador: Muhammad Asadullah

Muhammad Asadullah has been working in the field of Reliability, Diagnostics and Condition Monitoring for about 12 years. A CMRP, VA Catagory-3 Certified and undergone through extensive trainings and workshops in the field of Reliability, RCM, RCFA, FMEA and FMECA.

He had some interesting case studies published and presented in international journals and conferences. Moving on to achieve excellence, he has....

- Muhammad Asadullah

- ENGIE (Uch Power Private Limited)

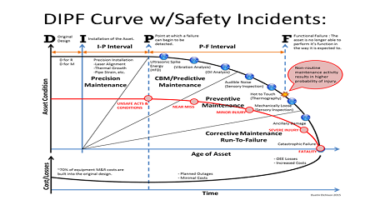

The Relationship of Equipment Reliability, Failures, Potential Failure (P-F) Curve and Human Safety

This is the last of a three part series on Understanding the P-F Curve. The last article will be a brief review of the two earlier articles and ending with a focus on an article and presentation published by Dustin M Etchison, CMRP with Elanco Global Engineering that brings all the aspects of equipment reliability and safety together.

- Tod Baer

- Minnkota Power Cooperative Inc.

- 1

- …

- 8

- 9

- 10

- 11

- 12

- …

- 20