Case Studies and Stories

Nigeria LNG – Monitoring Strategy and Solution – A Visual Case Study by Brüel & Kjær Vibro

See how B&K Vibro resolved a critical vibration issue. This visual case study offers a behind-the-scenes look at the diagnostic process, featuring actual waveform and spectrum data, the identification of a bearing fault, and the expert insights of Mobius-certified analysts.

- Michael Hastings

- Bruel & Kjaer Vibro

RYAM’s Transformative Journey

RYAM, an industry leader, proactively integrated KCF Technologies’ Comprehensive Machine Health Platform solutions into their operations – resulting in remarkable improvements.

- Jeremy Frank

- KCF Technologies

9 Principles of an Effective PM Program based on Reliability Centered Maintenance (RCM)

In this article, I provide a brief history of the development of Reliability Centered Maintenance (RCM). And from there we explore 9 principles derived from RCM that will help you build an effective Preventive Maintenance Program.

- Erik Hupje

- R2 Reliability

How a 3D Geometric Survey Diagnosed Faults in a Grounded Tugboat

We received a call regarding a tugboat that had run aground. Our survey included measurements of the hull mating flanges, Z-Drive cones, gearbox mounting flanges, bell housings, stems, and starboard lower gearbox housing for parallelism…

- Tony Planamento

- Advanced Mechanical Enterprises/AME

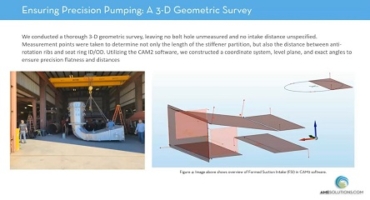

Ensuring Precision Pumping: A 3D Geometric Survey

We conducted a thorough 3D geometric survey of a submersible pump, leaving no bolt hole unmeasured and no intake distance unspecified. Utilizing the CAM2 software, we constructed a coordinate system, level plane, and exact angles to ensure precision flatness and distances…

- Tony Planamento

- Advanced Mechanical Enterprises/AME

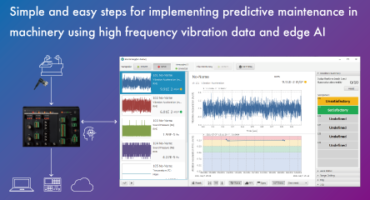

Simple and Easy Steps for Implementing Predictive Maintenance in Machinery using High Frequency Vibration Data and Edge AI

Currently, the most commonly used standard for maintenance processes is Time-based Maintenance (TBM) that involves inspection, repair, and part replacement at regular intervals. In general, TBM is not optimal and cost effective. On the other hand, Condition-based Maintenance (CBM) involves the utilization of various types of sensor data collected from machines to perform repairs or other countermeasures before malfunctions or anomalies occur, hence reducing the unnecessary cost of maintenance.

- Vikas Kumar Singh

- Macnica

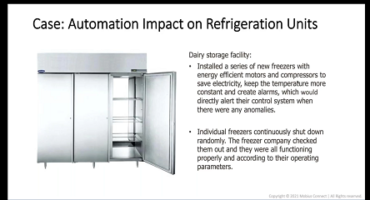

Impact of Automation on Refrigeration Units and the Role of Power Quality

Alan Ross, president of EPRA, presents a case study involving a dairy storage facility. When they installed a series of new freezers with energy-efficient motors and compressors, and they automated the system, individual freezers began shutting down randomly…

- Alan Ross

- Electric Power Reliability Alliance EPRA

SKF ENLIGHT COLLECT IMx-1

Wireless technology is often perceived as being more expensive and less secure than traditional wired methods, but the opposite is true. Wiring can be at risk of damage in harsh environments, both during operation and maintenance so going wireless reduces the cost of installation, minimizes risk and is an affordable way to retrofit machines needing monitoring.

- Christian Sahlin

- LumenRadio

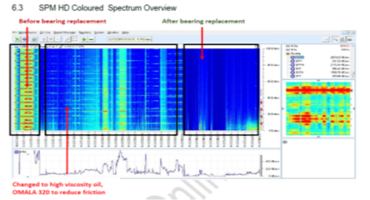

SPM Condition Monitoring Solution for Extruder

Welcome and enjoy the case study for extruder condition monitoring with SPM HD technology..

- Thamo Yellappan

- Eastwest Online (M) sdn Bhd

- 1

- 2