Case Studies and Stories

C&W Services Deploys Wireless Predictive Maintenance to Fix a Dated Walkaround Program

C&W Services implemented a wireless and AI-based predictive maintenance (PdM) solution from Petasense at a leading pharmaceutical and biotech client’s facility to automate data collection, improve asset reliability, reduce equipment downtime and achieve better resource allocation by continuous monitoring of critical machinery...

- Ken Madsen

- Petasense

Machine Monitoring and How ESA Technology Can Upgrade Your Plant’s Reliability

In many cases, the quality of the power supplied to the motor system may be the cause of a breakdown or failure. The result of poor “power quality” is usually long term and often overlooked as the source or contributor to the problem. Knowing the quality of the incoming power, along with the mechanical and electrical condition of motor and the mechanical condition of the drive are important at all facilities to maintain uptime & save money...

- Bill Kruger

- ALL-TEST Pro

Continuous Condition Monitoring Pays off at a Large Power Utility

A large power utility in Hawaii was looking for more frequent condition monitoring on their Balance of Plant (BOP) generation assets. They had experienced significant equipment failures that occurred between their scheduled quarterly walkaround condition monitoring routes. They decided to trial Petasense technology on 8-10 assets...

- Ken Madsen

- Petasense

Rotor Bar Fault Maintenance Issue: Vibration Sensor Alert

A 398 KW MV motor that runs a blower fan in a cement plant was showing strange behavior. The vibration equipment indicated vibration amplitudes that became chronic with the passage of time. The maintenance team not knowing what the issue was...

- Mark Koch

- ALL-TEST Pro, LLC

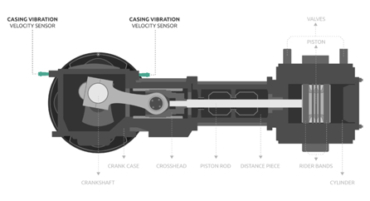

An Efficient Maintenance Strategy for Reciprocating Compressors

A client operates two reciprocating compressors, both of which are critical to the process. This particular plant produces a semi-finished product that is needed in another plant for the production of the end product. The reciprocating compressors are periodically inspected for rider band wear every 12 weeks, and to do so a shutdown is required.

- Lucas van Ruiten

- Istec International

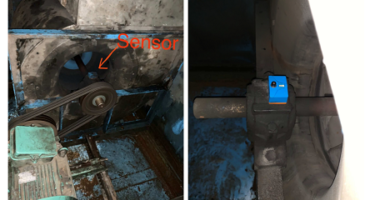

How to Include the Not-Approachable Equipment in CBM

It is always a challenge in the field of condition monitoring to monitor the machines which are not approachable, and that makes them prone to frequent failures.

- Akhil Jeet Rathore

- Indorama Eleme Petrochemicals Ltd

Duke Energy Takes Advantage of IIoT for Predictive Maintenance Applications

This case study investigates Duke Energy’s quest to replace its monthly, manual data collection practices with daily, remote data collection and monitoring.

- Alex West

- IHS Markit

Improve Electro-Mechanical Reliability Using Electrical Signature Analysis

Electrical Signature Analysis (ESA) is a predictive maintenance (PdM) technology that uses the motor’s supply voltage and operating current…

- Richard Scott

- ALL-TEST PRO

- 1

- 2