SKF ENLIGHT COLLECT IMx-1

SKF has developed a new condition monitoring system for improving rotating equipment performance programs on a scale previously considered uneconomic. The “SKF Enlight Collect IMx-1” combines SKF’s knowledge in machine health monitoring with LumenRadio’s patented wireless technology.

SKF’s mission is to be the undisputed leader in the bearing business and offer solutions around the rotating shaft, including bearings, seals, lubrication, condition monitoring, and maintenance services. By adding a battery-driven wireless vibration sensor to their condition monitoring system SKF will be able to provide added value to their core product – Bearings.

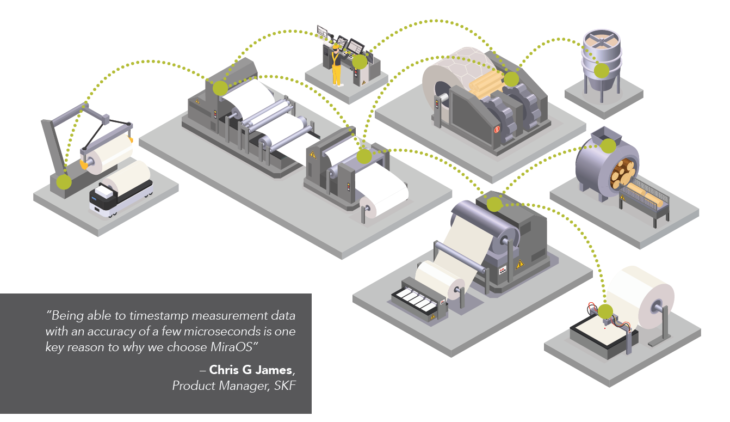

The new wireless monitoring system “SKF Enlight Collect IMx-1 enables improved Rotating Equipment Performance (REP) through faster, effective reporting on the state of components and assets, letting SKF take a wider grip of rotating performance equipment and rotating performance as a service.

THE PROBLEM – HARSH ENVIRONMENTS

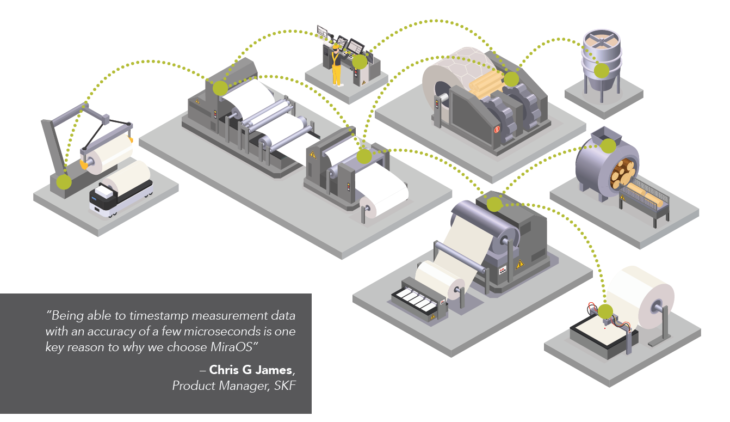

SKFs products are often used in extremely harsh industrial environments. It can vary between huge pipe jungles in paper mills to leaking pumps on water power plants. Using wires for communication in such environments can be very demanding. With its inflexibility to accommodate infrastructural changes and additions of new devices, a wired solution is expensive and not optimal for hard-to-reach areas. The harsh environment also put high requirements on the SKF products since it needs to be designed with high IP-rating, explosion-proof housing, and robustness to corrosion. This means that the battery can not easily, or at all, be changed, hence the need for long battery life length is key to success. This also puts a wireless technology to the test demanding it to navigate around obstacles, such as pipework and liquid storage tanks, instead of trying to punch through them. Hence SKF needed to find a wireless technology that could offer the highest reliability together with the lowest power consumption on the market.

THE SOLUTION – WIRELESS SENSORS

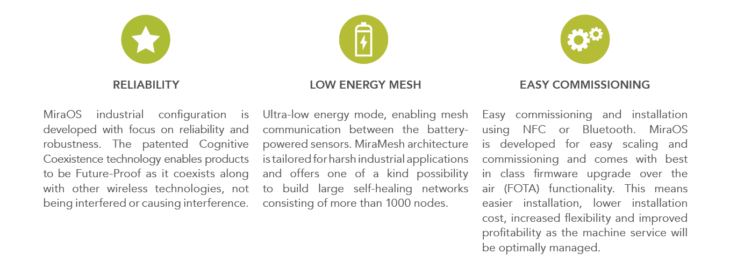

Choosing a wireless solution gave SKF the possibility to offer a wireless vibration sensor which is easy to install in harsh industrial environments. MiraOS is LumenRadio’s embedded operating system built for ultra-reliable wireless communication using minimal power to transmit data packets over a mesh network. With patented technologies, MiraOS is designed for industrial applications where interference and other types of disturbances are widely common.

COGNITIVE COEXISTENCE

The patented system for frequency agility scans the radio waves and detects the activity from other networks. It then uses that information to predict how the interference will evolve over time and then decides on what channels to use. This is done on every node in the system which avoids causing collisions with other networks, providing reliable wireless communication.

THE SKF ENLIGHT COLLECT IMx-1 SYSTEM

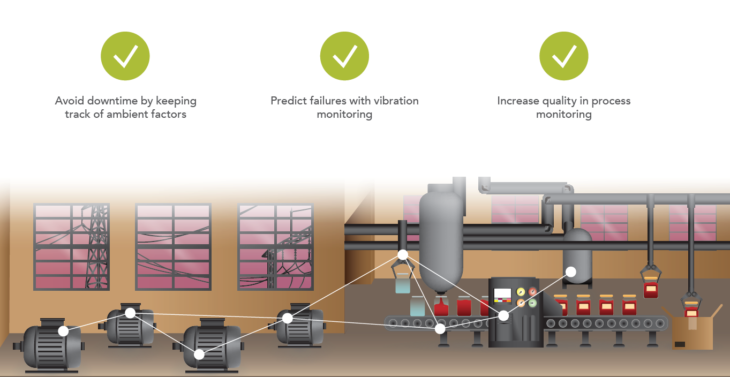

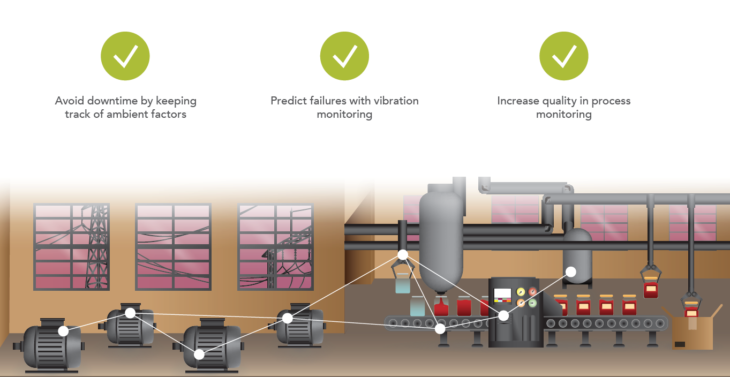

Automated machine monitoring for reliable rotation in heavy industries

When fitted to rotating equipment, the SKF system can economically automate vibration data collection. Predictive maintenance programs can be expanded, with data captured more often, which increases defect detection rates and leads to avoidance of costly unplanned machine shutdowns.

The new sensor combines SKF’s knowledge in vibration sensing and condition monitoring with LumenRadio’s expertise in low-power and reliable wireless connectivity. Furthermore, the technology provides Firmware over the Air functionality and precise timestamping of vibration data. This creates a future-proof foundation for SKF’s REP offering enabling scalability and new features.

With this system, plus online support, SKF can help customers improve machine performance through fast, effective reporting on the state of components and assets. Using LumenRadio’s innovative technologies SKF can provide inexpensive, easy to use, and easy to install condition monitoring systems, to enhance the Rotating Equipment Performance offering.

The sensor “SKF Enlight Collect IMX1”, when fitted to rotating equipment, helps customers enhance their predictive maintenance regimes, allowing them to avoid costly component failure and potential machine shutdowns enabling reliable rotation as a service.

MAJOR BENEFITS WITH THE SKF ENLIGHT COLLECT IMx-1

- Accurate vibration sensing running on battery

- Enables measurement in harsh environments

- Easy installation and commissioning

- Scalable, future-proof, and possible for retro-fit installations

- IMx-1 is a cost-effective sensor enabling the REP business model – offering Reliable Rotating equipment as a service

“Low power consumption was one of the main reasons SKF chose to work with LumenRadio. The possibility for sensors to run on a single battery for many years, usually, its entire lifetime, creates a perfect solution for harsh environments, such as paper mills or food manufacturing plants where you want to avoid unnecessary battery maintenance.”

– Chris G James, Product Manager, SKF

WHY MIRAOS FOR INDUSTRY?

MiraOS is LumenRadio’s embedded operating system for ultra-reliable wireless communication. MiraOS comes with an integrated radio stack that enables products to communicate wirelessly in building-wide, large scale mesh networks.

Predictive maintenance and process monitoring for new and retrofitted products needs to be cost-effective, flexible, and reliable. Wireless sensors with MiraOS inside in a perfectly applied mesh network, running on battery are more reliable, robust, and cost-effective than wired solutions.

With unique features for Industrial IoT applications, MiraOS is the perfect fit and will take your wireless products to an enhanced level.

“Wireless technology is often perceived as being more expensive and less secure than traditional wired methods, but the opposite is true. Wiring can be at risk of damage in harsh environments, both during operation and maintenance so going wireless reduces the cost of installation, minimises risk, and is an affordable way to retrofit machines needing monitoring.”

– Christian Sahlin

Business Area Manager, LumenRadio