Webinars

From Risk to Reliability: Detecting LDPE Reactor Bearing Faults Before Downtime

Webinar Description:

Low density polyethylene (LDPE) plays a dominant role in the packaging industry. Many LDPE products are made by the high-pressure ethylene autoclave process (free-radical polymerization), where the ethylene reactor mixer is the critical machine used for the polymerization.

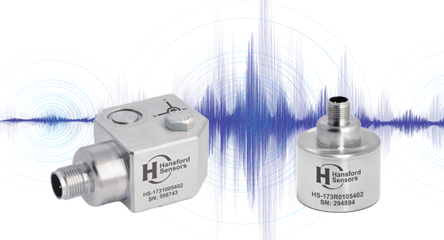

Managing this asset’s life-cycle costs is a challenge, as expensive downtime not only results from prematurely failing components of the reactor, but also from the process itself. Decomposition (decomp) can occur if the mixing, temperature, pressure and organic peroxides and comonomers and other modifiers are not properly balanced during polymerization. During decomp, the ethylene and polyethylene decomposes into H2 and CH4, which are highly explosive. Decomp can also occur if faulty bearings create a hotspot or affect the stirring action. Failed bearings are dangerous because metal particles can block the LDPE outlet channels. Bearings can prematurely fail because of the harsh environment, such as by deposits inside the bearing. Fortunately, it is possible to effectively monitor the condition of the bearings.

This webinar, presented by Mike Hastings from Brüel & Kjær Vibro, covers three individual case studies of monitoring defect reactor bearings. This proves that an effective condition monitoring solution with the proper monitoring techniques is an absolute imperative for this type of machine.

About the Presenter:

Michael Hastings is a Sr. Application Engineer with Brüel & Kjær Vibro, where he has been working for the past 33 years. Here he has worked with developing various condition monitoring strategies and optimization techniques for various machines, and is currently working with strategic market development, analysis and communications. He has written numerous articles, papers and webinars on machine condition monitoring, especially in the LNG industry. He is also convenor for an ISO work group for creating standards for condition monitoring and diagnostics of machines.

Webinar Registration - From Risk to Reliability: Detecting LDPE Reactor Bearing Faults Before Downtime

Please complete the form to continue. Your personal information is treated with care and will be handled in accordance with GDPR regulations.