Condition Monitoring

Continuous Monitoring Systems: Choosing the Frequency of Data Collection

The chemical processing industry incorporates a broad range of machinery, both rotating and reciprocating, which are monitored using various types of sensors and other advanced technologies that measure equipment performance/health. The determining factor as to what must be monitored and how to do so is the criticality of the equipment, based on its importance to the process and/or operation.

- Ernest McCurdy

- T.F. Hudgins (division of Allied Reliability)

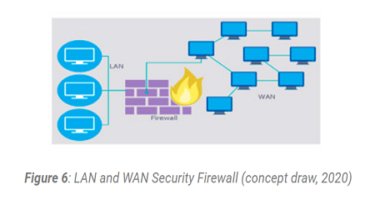

The Reliability Engineer’s Guide to Understanding IIoT Device, LAN, and WAN Security

As wireless sensor technology begins to take the leading edge within the industrial internet of things community, a new era of data security has emerged that requires diligent thought and consideration on the part of end users, system integrators, and key stake holders. Critical machine health and process data being transmitted wirelessly and hosted internally as well as externally creates an entirely new series of security concerns that must clearly be understood to maximize the value of the technology. This presentation will focus on the key security tools available to end users to ensure the security of their data when deploying wireless sensor networks and hosting data internally as well as externally to their organizations.

- Michael Howard, DSc

- ERBESSD-INSTRUMENTS

Let’s Talk About Food Grade Grease

Food grade grease offerings can play a significant role in preventing costly damage brought on by severe operating conditions in food, beverage and pharmaceutical applications.

- John Sander

- Lubrication Engineers

Important Aspects about Condition Monitoring

Technology in predictive maintenance is growing fast, and so is Condition Monitoring which is one of the its most important activities. In particular, the wireless sensors in Condition Monitoring came to change completely the way we used to see machinery reliability.

What is Condition Monitoring? What do we need to learn about modern technologies applied in it? Well, I am a Vibration Analysis technology developer and I invite you to take some time to read this few tips I have written for you.

- Dr. Thierry Erbessd

- Erbessd Instruments

Aluminum Complex Thickener Greases

Lubricant has the power to increase equipment uptime and enhance bottom line profitability.

- John Sander

- Lubrication Engineers

Electrical Frequencies Calculation and AC Motor Faults Patterns. Part 2

In the Part 2 the practical example will be analyzed.

Let’s look the background and calculate the most common frequencies produced by motor that potentially will be required for further analysis.

- Pawel Lecinski

- CMRP

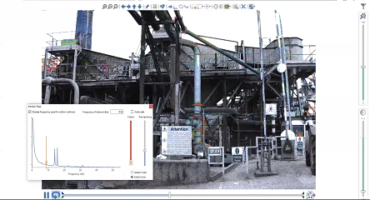

Demo of Motion Maps and Frequency Filtering

Motion amplification allows you to see things a normal camera can't show. These amplifications show you all frequencies but also allow you to isolate individual frequencies, and visualize faults. The program is user friendly, color coded, and gives you vibration data in an easy to export Mp4 format.

- Jeff Hay

- RDI Technologies

Resonance & Natural Frequency

Have you ever tried to balance a fan and its vibration won’t go down? No matter what you do, do you know what Resonance is?

3 Tips to diagnose Resonance and 6 ways to correct it below.

- Dr. Thierry Erbessd

- Erbessd Instruments

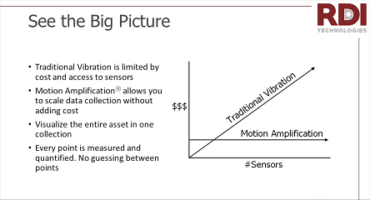

Fundamental Measurement of MA

Imagine each pixel on a camera becomes a sensor; you can now measure millions of data points. The fundamental measurement of Motion Amplification is displacement, which increases capabilities of measurement types and allows you to easily use it with other technologies to extract vibration data.

- Jeff Hay

- RDI Technologies

- 1

- …

- 6

- 7

- 8

- 9

- 10

- …

- 20