Webinars

Watching the Invisible – Rotor Torsional Vibration Measurements Using Vorso Transducers

The presentation covers the physical principles behind the operation of the eddy current transducer system, outlines the steps for successful implementation of measurements on industrial machines and provides an overview of sample project results.

- Piotr Mialkowski

- Baker Hughes

Watching the Invisible – Rotor Torsional Vibration Measurements Using Vorso Transducers

The presentation covers the physical principles behind the operation of the eddy current transducer system, outlines the steps for successful implementation of measurements on industrial machines and provides an overview of sample project results.

- Piotr Mialkowski

- Baker Hughes

Leveraging AI & Analytical Efficiency for Predictive Maintenance

In today's rapidly evolving digital landscape, organizations across various sectors find themselves inundated with enormous volumes of data. This presents both a challenge and an opportunity. Successfully navigating this sea of information requires not just traditional analytical methods, but the integration of more advanced computational techniques to drive efficiency and innovation.

- Jeremy Frank

- KCF Technologies

The Reliability No One Talks About

Most of the time, we are able to define and explain reliability engineering to others. It is also possible that reliability practitioners may discuss job cards, oil analysis, vibration analysis, ultrasound, root cause, oil analysis, vibration analysis, and motor current analysis in addition to other topics. If we are so knowledgeable, why do most implementations of it fail at least 50% of the time?

- Benjamin Masinge

- ZAG Mining and Construction

Project Management: A Key Tool for Increasing Equipment Reliability

We will explore how project management principles can enhance equipment reliability. Key topics will include defining clear goals, establishing structured processes, and leveraging data to drive decisions. By integrating project management with maintenance strategies, attendees will learn how to optimize resources, reduce downtime, and improve equipment reliability.

- Angelica Gonzalez

- Hexpol Compounding Americas

Reliability Analytics Explained

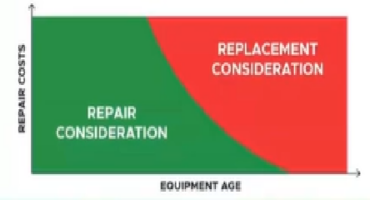

Reliability Analytics provides a collection of statistical tools that apply reliability engineering principles to help you make tactical (short-term) and strategic (long-term) decisions for maintenance and operational equipment management activities by analyzing historical failure data to identify trends and predict future failures.

- Vinoth Kumar

- TRANSCO

Master your OEE through Optimized Ecosystem Engagement

Solutions for manufacturing can be complex, especially because of the varied nature of equipment, hardware, software, and solution providers. Overall Equipment Effectiveness (OEE) is a broad metric, or compound metric, that encompasses multiple departments, personnel, and solutions.

- Adam Napolitano

- Triple Circle Partners

How to Manage a Successful Digital Predictive Maintenance Program

• Asset Governance – You Need a Good Partner and a Well-Defined Process to Allow Governance.

• Critical assets optimizations - Importance of Healthy Structure PdM Plan Guideline

• Digitalization to Optimize Resources – IOT / A.I / Data-Driven Industries Integration.

• Main KPIs and Benchmarks.

• Complex Systems Enhancement

- Silvio DosSantos

- SEMEQ

Optimizing Maintenance Planning: Management’s Call to Do Things Right!

We'll uncover specific management wrong practices impacting the Maintenance Planning function and CMMS/EAM Implementation. Limited by time, examples will shed light on pitfalls, offering insights into navigating challenges imposed by suboptimal decisions and knowledge gaps.

- Ahmed Kotb

- Self-employed

- 1

- 2

- 3

- 4

- …

- 15