Many companies and organizations prepare periodic reports to monitor performance which include tables and charts of key performance indicators, but many of these reports are not used optimally as required to achieve the desired goals.

This working paper presents the basis and pillars for selecting, measuring and using KPIs through 4 main keys…

Introduction and definition:

Competitiveness requires measures that accurately reflect our future business performance; these measures allow focusing our priority items and not waste resources on non-value added initiatives or programs.

It’s said that “It is not possible to manage what you cannot control and you cannot control what you cannot measure” Peter Drucker

For that, Performance indicators are used by leaders to lead. The leaders must set a clear direction, focusing on the company vision. Then they require good navigation tools, called KPI to help them steer the organization.

The strategic approach to management focuses on effectiveness and results.

Key Performance Indicators (KPIs)

are quantitative and qualitative measures used to review an organization’s progress against its goals. These are broken down and set as targets for achievement by departments and individuals. The achievement of these targets is reviewed at regular intervals.

Maintenance Key Performance Indicators (KPIs)

There are number of management indicators used to measure the effectiveness of a maintenance program.

The most useful indicators are numerical. The numerical, or quantified indicators, often referred to as “metrics”, can be expressed as goals and objectives, measured and displayed in several ways for the purpose of analysis and management decision making.

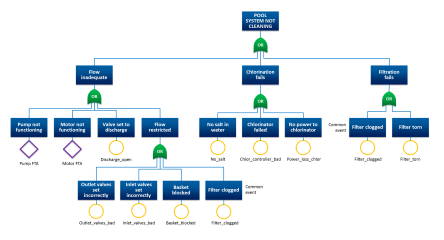

Based on previous definition KPI is a control tool in reliability and maintenance program, and as per ISO 9001; control element means monitor or measure the performance, compare result with goal or benchmark, analyze the gap –positive or negative-, and recommend corrective action.

To enhance control of reliability and asset management program, the following 4 keys are essentials while using KPIs:

1- Why use KPI?

The measurement of performance is important as:

– It identifies current performance gaps between current and desired performance,

– It provides indication of progress towards closing the gaps.

They are not to be used

o To show that individuals are not doing their jobs.

o Forego gratification, that is, for comparison with other company to show how much better one company is than another.

o To show “we are just as good as everyone else in our market, so we don’t need to change”.

Properly utilized

o They should highlight opportunities for improvement,

o To highlight a soft spot and then be further analyzed to find the problem,

o Ultimately the indicator can then point to a solution to the problem.

2- KPI selection

A key principle of performance management is to measure what you can manage.

Carefully selected key performance indicators identify precisely where to take action to improve performance.

Critical few (key) indicators aligned throughout the organization that measure controllable performance and contribute towards achieving the organization objectives.

3- The formula and value

Metrics should consist of a descriptor and a benchmark.

Descriptor: is a word or group of words describing the units, the function, or the process to be measured. Based on this descriptor the formula and all its terms should be very clear defined.

Benchmark: is a numerical expression of a goal or objective to be achieved. It is that against which one measures one’s performance. It can be an absolute number or a range. Which may be derived from the organizational goals and objectives or they may be selected from a survey performed with similar organizations.

4- Integration and balance

Performance indicators should be integrated and interdependent to provide an overall perspective on the reliability and asset management program’s goals, strategies, and specific objectives.

All the program phases should be regularly measured and evaluated with appropriate indicator that should be carefully selected to give a complete figure of progress, that’s why they should be integrated and balanced between:

– Time indicators, resources indicators, and cost indicators.

– Leading and lagging indicators.

Finally, Managers and workers at all levels of the organization need to participate in the development and refinement of KPIs in their functional areas, thereby generating a sense of ownership. It is this sense of ownership that supports the continuous improvement process.