Condition Monitoring

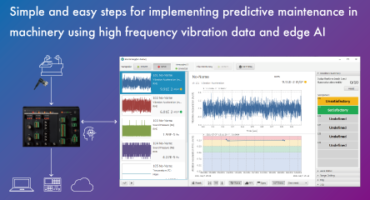

Simple and Easy Steps for Implementing Predictive Maintenance in Machinery using High Frequency Vibration Data and Edge AI

Currently, the most commonly used standard for maintenance processes is Time-based Maintenance (TBM) that involves inspection, repair, and part replacement at regular intervals. In general, TBM is not optimal and cost effective. On the other hand, Condition-based Maintenance (CBM) involves the utilization of various types of sensor data collected from machines to perform repairs or other countermeasures before malfunctions or anomalies occur, hence reducing the unnecessary cost of maintenance.

- Vikas Kumar Singh

- Macnica

The New Normal in Predictive Maintenance

What does machine health monitoring look like in an era of the online workday, personnel shortages, and supply chain hang-ups? These recent trends have influenced practices in predictive maintenance—including how data is collected, shared, and analyzed. Read on for five condition monitoring solutions to avoid manufacturing delays and optimize workflow.

- Bob Martin

- IMI Sensors

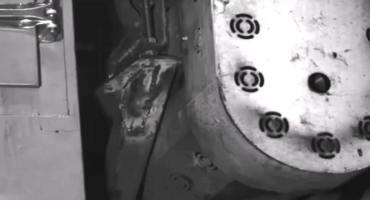

Motion Amplification Case Study: Structural Looseness

This case study features a convection oven fan used in the customer's production process. Multiple welds and other repairs were made prior to the inspection. A service team was called in to balance the fan, but with Motion Amplification it quickly became clear that there was a serious structural issue.

- Andrew Dougherty

- RDI Technologies

Vibration Analysis- The Tools for Success

We dive deep in conversation about our experiences in vibration Analysis and why we think it is so important for industry.

- Will Bower

- Maintain CM Ltd

On-Site Installation

Some of the manufacturers of rotating equipment are individually testing and certifying their machines before they leave the facilities. But that does not necessarily mean that whole systems will be integrated together and work properly.

- Sven Fleischer

- Easy-Laser

Fluting: Beyond the Motor

Before scrolling past what may appear to be another boring article about fluting, VFD’s, grounding brushes and ceramic bearings, I urge you to read on and join in the discussion.

- Matthew Knuth

- SPM Instrument

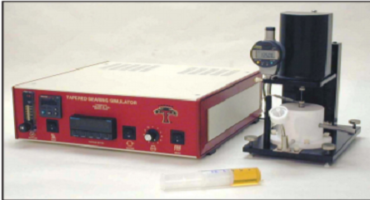

Putting the Simple Back into Viscosity

Simply stated, viscosity is defined as the internal resistance of a fluid to flow. That doesn’t sound too difficult, does it?

- John Sander

- Lubrication Engineers

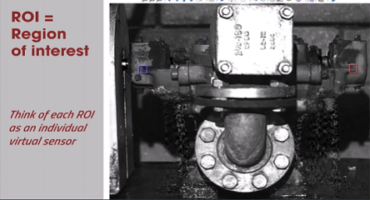

Visualizing Phase Using Motion Amplification Motion Vectors

One of the great things about Motion Amplification recordings is the fact that all of the data is recorded simultaneously. Because of this, there is a lot of phase information embedded in the data.

- Chris Wills

- RDI Technologies

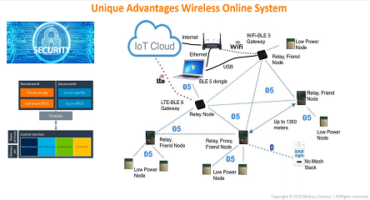

How Wireless Monitoring Impacts Safety and Security

Are you considering wireless monitoring for your plant but worried about security issues? David Howard addresses those concerns and also discusses how wireless monitoring can improve the safety of your plant, including during pandemics…

- Michael Howard, DSc

- ERBESSD-INSTRUMENTS

- 1

- …

- 3

- 4

- 5

- 6

- 7

- …

- 20