Condition Monitoring

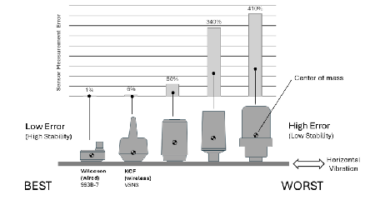

Which Wireless Vibration Sensors Can You Trust?

Wireless vibration sensors are an enabling technology driving the biggest improvements in asset health and reliability since the advent of route-based vibration monitoring. These sensors are one of the most important components of predictive maintenance programs because the data they generate is foundational to analytics, directing corrective maintenance tasks, and ultimately plant floor engagement with predictive maintenance.

- Jacob Loverich

- KCF Technologies

The Case for Remote Predictive Maintenance Services

The benefits of proactive maintenance naturally come from optimized asset reliability and performance. However, potential bottlenecks can still obstruct progress. Proactive maintenance has traditionally been filled with various predictive maintenance (PdM) programs that generally gather comprehensive intelligence on machinery conditions for analysis...

- Michael Dwyer

- Mobius Institute

Operator-Driven Safety and Reliability

In today’s episode, we’re going to chat about a novel and exciting approach to safety reliability which has been picking up speed in the world of facilities management. The concept is called operator-driven safety and reliability, or ODSR for short.

- Brad Nanna

- IRISS Inc.

Enterprise Asset Management Systems

In today’s episode of RED Talks, we will chat about enterprise asset management systems, what they are, and how your organization can utilize such a system to save money, increase efficiency, and improve accountability.

- Brad Nanna

- IRISS Inc.

Training and Qualifications for Accurate Inspections

In today’s episode, we are going to chat about training, certification and qualifications needed to perform safe and accurate inspections on reliability equipment.

- Brad Nanna

- IRISS Inc.

RED Talks- Episode 1

In this episode, Brad Nanna, Senior Vice President of Sales and Marketing at IRISS, will talk about NFPA 70B, the set of revised standards that came out in 2023, and we're going to try and get a better understanding of what those standards mean for our electrical inspections, especially when it comes to safety.

- Brad Nanna

- IRISS Inc.

9 Principles of an Effective PM Program based on Reliability Centered Maintenance (RCM)

In this article, I provide a brief history of the development of Reliability Centered Maintenance (RCM). And from there we explore 9 principles derived from RCM that will help you build an effective Preventive Maintenance Program.

- Erik Hupje

- R2 Reliability

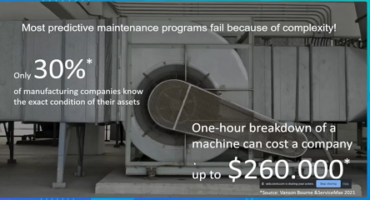

Why Do Most Predictive Maintenance Programs Fail?

Christian Benk, director of product management at B&K Vibro, draws from an industry study and his own experience to describe why most companies experience failure in their predictive maintenance programs…

- Christian Benk

- BK Vibro

Repair or Replace? – CONNECT Conversations

Answering this question requires considerable information and analysis, and judgment. For example: What’s the current state of the asset? We’ll explore these and other questions, and provide guidance in helping you answer this fairly frequent, fundamental, and ofte3n complex question...

- Ron Moore

- RELIABILITY CONNECT

- 1

- 2

- 3

- 4

- …

- 20