If you want the equipment and assets in your industrial facility to stay up and running, you’ll need a good reliability program. Reliability programs are designed to increase and maintain the performance of a plant’s equipment by identifying potential failures and eliminating their causes and reducing the possibility of production failures and stalls while enhancing safety.

Reliability programs and engineering are closely linked with the longevity and dependability of parts, products, and systems.

RDI’s patented technology measures deflection, displacement, movement, and vibration not visible to the human eye. Using the Iris™ video acquisition software in conjunction with our analysis software and processing algorithms, Motion Amplification® technology can extract and harness meaningful data to relay problem areas via video.

Throughout the processes and steps comprising any reliability program, the Motion Amplification® proprietary video processing technique can play an essential role.

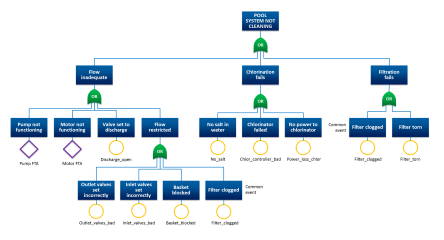

Root Cause Analysis and Troubleshooting

Troubleshooting the problem and its root causes, and not just the failure at hand, makes maintenance and repairs more effective. Troubleshooting will always be a multi-step process, but it can be made more efficient.

Motion Amplification® offers key advantages. Being able to observe a machine and all of its surrounding components as it operates in real time gives you the total picture. Failures can have multiple causes, and you’ll want to see and correct all of them. Such a comprehensive look also reduces trial-and-error time, getting you to solutions that much more quickly.

Similarly, root cause analysis takes a systematic approach to identifying the root causes of problems or events. Instead of merely treating the symptoms, root cause analysis seeks to get at the source of the problem.

Motion Amplification® is a superior root cause analysis tool. By visualizing the actual movements and vibrations that machinery experience, the area of concern can be pinpointed and seen instead of inferred from charts and graphs. Cut down on the trial and error processes when looking for the problem and get right to the root cause.

Corrective Action

After the root cause of a problem has been identified, taking corrective action is next. As with finding the root cause of a problem, corrective action steps should be all-encompassing and make sure that the fault or other mechanical issue is addressed in its entirety and that the corrective action does not introduce other issues.

Because Motion Amplification® can provide a complete picture of the problem, using it helps to make sure that all causes of problems are identified. Corrective action, then, can sufficiently address all underlying problems. For example, Live Motion Amplification® can be used during the process of tightening a base. While it is being tightened, you can see in real time if the resulting vibration is decreasing to normal levels or the unwanted vibration is being removed.

Capturing Equipment Performance Data

Effective improvement processes have to measure success and make decisions using empirical data. In fact, maintenance best practice involves maintaining an asset’s historical data archive for future use.

While such data is already defined in some situations, more data and better data can make all the difference. RDI’s Motion Amplification® process involves using a high definition and high dynamic range video camera and accompanying software to turn every pixel into an independent sensor creating millions of data points in an instant. This data can be stored over time and reanalyzed at any point in the future to visualize and measure changes in performance of an asset.

Mean Time Between Failures

No piece of equipment will last forever, but increasing the time between failures and downtime should be a goal of any reliability program.

Reducing failures and disruptions can be a matter of better maintenance and machine monitoring. The amount of data produced by a short video is significantly higher than the extent of data gathered with traditional vibration analysis and visualization of that data offers a quicker path to discovering the cause of unwanted vibrations. So, a better understanding of the causes behind repeat failures becomes more clear.

Reliability Process Failure

When a machine breaks, technicians scramble to fix it — that may be a universal law. But when the job’s done, how soon until the machine breaks again? A reactive system can produce an endless cycle of breakdowns and repairs.

There are any number of reasons for equipment and machinery to fail. But taking a comprehensive look at such failures and how fixes can encompass more than just the broken component improves reliability all around. You’ll need the full, clear picture, which is exactly where RDI’s motion enhancement technology can help.

Condition Monitoring

Condition monitoring entails observing a certain aspect of a machine’s performance to detect changes that could indicate a developing fault. Carrying out condition monitoring both quickly and easily is key to reliability testing.

RDI’s non-contact Motion Amplification® testing method uses the Iris M™ platform to identify equpiment’s potential problems and failure risks without applying affixed sensors or requiring or extending downtime, streamlining the condition monitoring process all around.

Communication

Any plant and industrial facility’s personnel includes multidisciplinary teams to carry out various roles. No matter the industry, sometimes it can be tough to make sure everyone’s speaking the same language and fully understanding processes and problems.

Pictures and visuals, however, provide a universally understandable means of communicating. RDI’s video Motion Amplification® technology communicates data clearly and efficiently even to non-technical personnel. By converting data to a video that clearly shows problem areas and faults, structural and maintenance problems can be easily understood across the board.

RDI Technologies – Here To Serve You

RDI Technologies was founded in 2013 to commercialize video-based sensing technologies theorized in the lab at the University of Louisville. Since the beginning, our commitment has been to innovate using relatable video technology and easy-to-use software. In 2015 RDI Technologies invented and began development of the first-to-market Motion Amplification® platform technology for motion and vibration detection and analysis using video. This product was released to the market in 2016 with very quick market adoption. With the release of the Iris M™, RDI created a new category of motion and vibration detection and revolutionized the way the Predictive Maintenance industry saw motion.

RDI has continued its commitment to innovation over the last 3 years with the release of the Iris MX™ that expanded the use of Motion Amplification® to high-speed applications and the release of the Iris CM™ which enabled the user to continuously monitor their products, processes, and machinery. We believe our customers are instrumental in our innovation, and we work directly with them to create products, solutions, and software updates that solve their toughest problems and complement or replace the current tools in their toolbox.