In the ideal world of Industry 4.0, organizations will have better equipment with wireless connections and sensors linked to a system that can visualize and control the entire production line and make autonomous decisions. Industry 4.0, in other words, describes the ever-increasing trend towards automation and data exchange.

Predictive maintenance is a low-hanging fruit when it comes to Industry 4.0. By analyzing production and maintenance data, we can identify patterns and predict downtimes before they happen. But not every organization is as ready for predictive maintenance. Organizations should be talking about building a vision around Industry 4.0, but, in a market driven by rapid change, many cannot keep up. In the midst of a digital transformation, most don’t yet have scalable, reliable solutions for implementing their Industry 4.0 strategies.

At I-care, we’ve defined 7 steps an organization can take to become an organization ready for Industry 4.0. We call this our Industry 4.0 roadmap. It’s the foundation for organizations that still have yet to begin their Industry 4.0 journey, but it also offers insight into what the starting point for your organization will be once you’ve already taken steps in the Industry 4.0 direction.

Step 1: Assess

The first step is all about assessing readiness and whether your organization has implemented all the essential building blocks for Industry 4.0. To increase chances of success and reduce novice mistakes, you needs to know where you are now, where you want to go, and how to bridge that gap.

Step 2: Identify

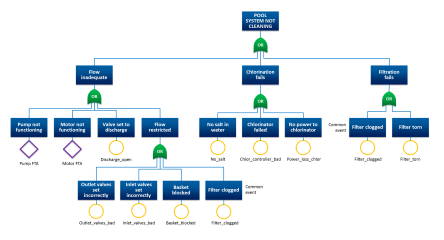

In this stage, specific potential projects are identified based on the available historical failure data, followed by an evaluation of their value and feasibility. An in-depth technical and failure mode analysis is also helpful for clearly identifying the project scope. This analysis makes it possible to eventually build a business case and propose technical solutions.

Step 3: Generate

Once you’ve gotten a handle of your current situation and have identified options for optimization, you now have to implement the technical solutions needed to generate the relevant data. Recent innovations in IoT make it possible to reduce costs for connectivity and integrate with existing ISA 95 data architecture.

Step 4: Collect

After generating the data, you need to collect it. A lot of data sources may appear isolated and seem to fail to provide enough information. In terms of Industry 4.0, however, combining all of the relevant data sources offers a better and smarter base to create valuable insights.

Step 5: Analyze

All of the collected data then needs to be analyzed to draw solid conclusions. The traditional way was for analysts to interpret the data, line-by-line, looking for patterns. With the Industry 4.0 evolution, this data can now be prepared in an automated way by using computing power to facilitate or even completely handle that data analysis.

Step 6: Visualize

If there is a problem, it needs to be communicated clearly and transparently. To gain insights into the big picture, problems, and possible solutions, the output needs to be visualized with the help of user-centric dashboards.

Step 7: Act

The last stage of the roadmap is the most crucial one. All of the previous steps would be worthless if there is no follow-up with appropriate action. It’s all about effective interventions in the field at the right time.

Wherever you are on the road to Industry 4.0, we are here to help. Plan your next steps together with I-care.